Drop-in masterbatch

Biodegradable & Compostable

Can be recycled

Made in the UK

What is Biotransformation?

Polymateria’s revolutionary Biotransformation technology is a new approach to ensuring that plastic which has escaped refuse streams can fully biodegrade in the natural environment.

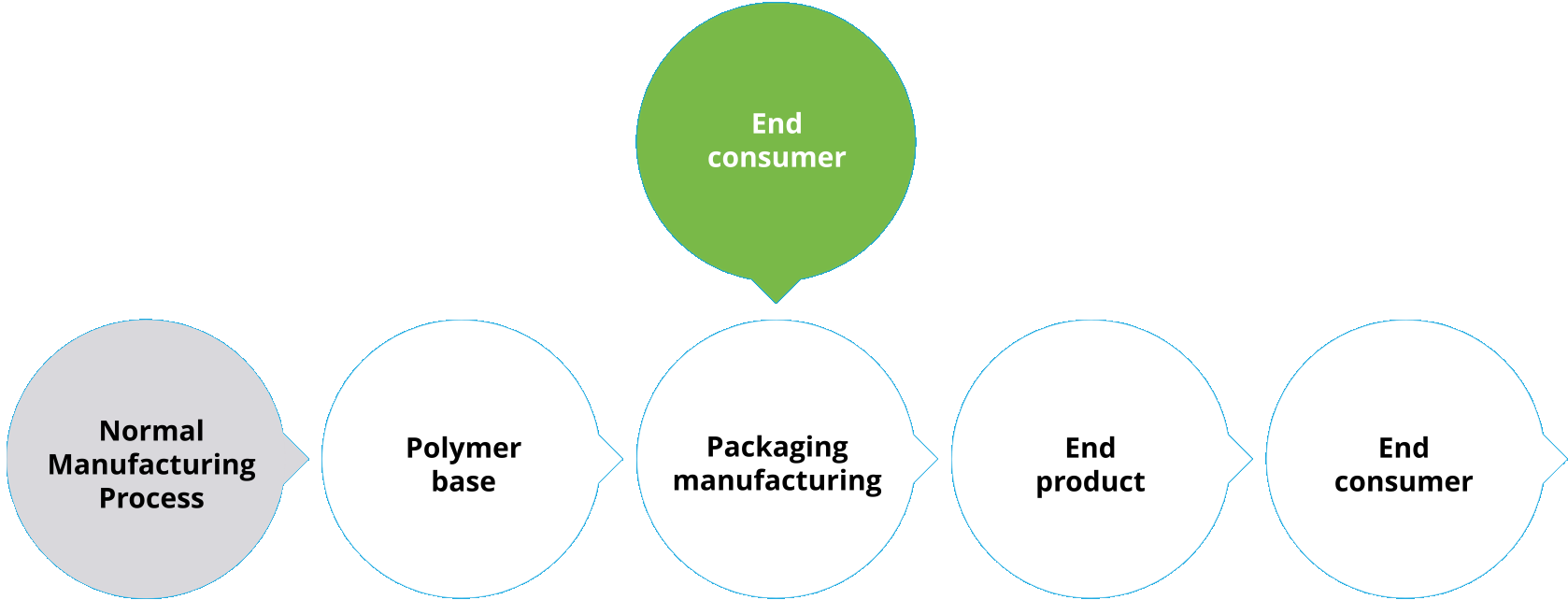

How it’s applied

- Formulated as a drop-in masterbatch

- Each Masterbatch is tailored to the resin’s footprint, application profile and required use life

- Fully compatible with the normal plastic conversion processes

- Typical loading rate: 2% weight percentage (wt%)

How it works

1.

Dormant application

Giving recycling every chance to happen and maintaining full shelf lives during the life of the packaging, our proprietary formulation lies dormant – users wouldn’t even know it’s there (the way it should be).

2.

Chemical transformation

In line with the agreed timing, the formulation gets to work by triggering a catalytic process that actively targets the crystalline regions within polymer chains to radically cleave them apart.

3.

Biological consumption

With a reduction in length of the carbon chains, nature is able to reengage with the product as it is handed back its ability to decompose within the environment via nature’s four agents of decay – light, air, moisture and microbes.

4.

No microplastics

Our technology results in absolutely no microplastics whatsoever. All that’s left is carbon dioxide, water and microbes (biomass).

Products

Polymateria offer 2 different products to suit different applications.

Short service life (<6 months)

Polymateria’s DegrAid product is designed specifically for end of life situations where recycling is not an option, e.g sealant films.

Rigid packaging – long service life (6 months – 3 years)

Polymateria’s Cycle+ brings advanced biodegradation technology to different types of plastic, without affecting its recyclability within the product’s use life.